Absolutely new commercial product on the market

Read more

Read more

You can put it at any place: near the restaurant or bar – at any place where beer is popular

Unique

MOBILE

BREWERY

MOBILE

BREWERY

Connection

on a new place

takes 30 minutes

on a new place

takes 30 minutes

Required utilities: water– pipe

1000l/day; sanitary drain

pipe 2; and electric power

receptacle 45 kWt

1000l/day; sanitary drain

pipe 2; and electric power

receptacle 45 kWt

No more additional

expenses on construction

and decoration works

expenses on construction

and decoration works

Production price

of 0,5 l of beer is 0,2$

of 0,5 l of beer is 0,2$

Up to 7 varieties

of beer

at the same time

of beer

at the same time

Production capacity:

250 - 1000 l of beer /day

250 - 1000 l of beer /day

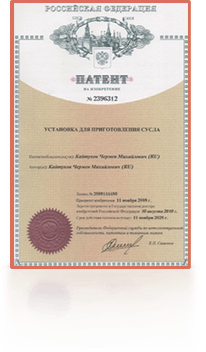

Unique

patented technical and technological,

solutions have given us an opportunity

not only to fit all technological process in

such a restricted space but also are giving to the

future owners a possibility to brew not only

standard classical types of beer but also to brew

unique types of beer which can not be

reproduced on any other equipment of any other

supplier in the WORLD!

patented technical and technological,

solutions have given us an opportunity

not only to fit all technological process in

such a restricted space but also are giving to the

future owners a possibility to brew not only

standard classical types of beer but also to brew

unique types of beer which can not be

reproduced on any other equipment of any other

supplier in the WORLD!

Detailed 3D Tour

You are a restaurant owner?

Why You need particularly a mobile

brewery?

brewery?

You

do not have

enough space

for the

brewery?

do not have

enough space

for the

brewery?

You do not want to

decrease the quantity

of seats in the

restaurant installing

a brewery inside?

decrease the quantity

of seats in the

restaurant installing

a brewery inside?

You have a

good decoration in

Your restaurant and you

do not want to damage

or change it?

good decoration in

Your restaurant and you

do not want to damage

or change it?

Do you want to operate

a brewery abroad and

you are afraid of high

cost of remote

investment project?

a brewery abroad and

you are afraid of high

cost of remote

investment project?

You lease

the space

and you do not

want to

invest money

to somebody´s

property?

the space

and you do not

want to

invest money

to somebody´s

property?

You do not want to

stop you restaurant for

an installation

of a brewery and

reconstruction work?

stop you restaurant for

an installation

of a brewery and

reconstruction work?

You have some

difficulties in obtaining

a permissionfor

a reconstruction works

and installing a brewery

in you restaurant?

difficulties in obtaining

a permissionfor

a reconstruction works

and installing a brewery

in you restaurant?

Are you worried

about

a business project,

which would

not have

to pay the cost?

about

a business project,

which would

not have

to pay the cost?

THEN Mobile Brewery IRISTON –

is Your Choice

is Your Choice

| Description | Measuring unit | |

| length | mm | 12 192 |

| width | mm | 2 438 |

| height | mm | 2 895 |

| weight (if a brewery is full of malt and beer) | kg | 17 000 |

| weight (without malt and beer) | kg | 12 000 |

| Installed electrical capacity | kWt | 45 |

| Power consumption per hour | kWth | 20 |

| Outside temperature rate of brewery operating | °С | -30 - +30 |

| Reserve power supply system (option) | yes | |

| Production capacity | l of beer/day | 250-300 |

| Maximum varieties of beer at the same time | 7 |

For mobile brewery capacity increasing up to 1000 l of beer/day we offer a

second container equipped with: 20-25 fermenting tanks installed inside;

separate mounted diesel generator for ref containers modernized to 380V;

and glycol chiller with buffer tank.

- • УНИКАЛЬНЫЙ ПЕРЕДВИЖНОЙ ПИВЗАВОД

- • УСТАНОВКА В ЛЮБОМ МЕСТЕ: У РЕСТОРАНА ИЛИ РАЗВЛЕКАТЕЛЬНОГО ЦЕНТРА - ВЕЗДЕ, ГДЕ ЛЮБЯТ ПИВО

- • ПОДКЛЮЧЕНИЕ НА НОВОМ МЕСТЕ ЗА 30 МИН

- • ДЛЯ ПОДКЛЮЧЕНИЯ ТРЕБУЕТСЯ ТОЛЬКО ВОДА – ТРУБА 15 ММ, КАНАЛИЗАЦИЯ – ТРУБА 50 ММ И ЭЛЕКТРИЧЕСТВО 10 КВТ

- • БОЛЬШЕ НИКАКИХ ДОПОЛНИТЕЛЬНЫХ ЗАТРАТ НА СТРОИТЕЛЬСТВО, МОНТАЖ, ПЕРЕНОС ПИВЗАВОДА

- • СЕБЕСТОИМОСТЬ 1 Л ПИВА – 20 РУБ

| Передвижные МИНИ ПИВЗАВОДЫ IRMOBILE | ||||

|---|---|---|---|---|

| Производительность л/сутки | 250 | 500 | 1 000 | 2 000 |

| Комплектация SMART ЦЕНА млн. руб. | 8.7 | 12.7 | 17.2 | 29.1 |

| Комплектация CLEVER ЦЕНА млн. руб. | 6.4 | 10.2 | 14.7 | 25.0 |

Передвижной МИНИПИВЗАВОД IRMOBILE изготавливается в 2-х стандартных комплектациях:

- CLEVER:

- 1. Холодильная машина с накопительным баком гликоля, обеспечивает возможность охлаждения пива

- 2. Система подготовки воды, обеспечивает подготовку воды до нужного качества

- 3. Система жизнеобеспечения: вентиляция, кондиционирование, отопление, освещение, ультрафиолетовая дезинфекция

- 4. Воздушный компрессор, обеспечивает минипивзавод сжатым воздухом для систем автоматизации и аэрации сусла.

- 5. Солодо-дробилка снабженая системой пылеудаления и весами

- 6. Варочный порядок ПОЛУАВТОМАТ удвоенной мощности

- 7. от 8 до 20 лагерных танков для брожения и дображивания пива

- 8. Специальный СИП насос для мойки ЦКТ

- 9. Парогенератор дизельный

- 10. Услуги пивовара с наладкой 2 сортов пива на выбор

- 11. Прямая гарантия на все узлы и детали – 12 мес.

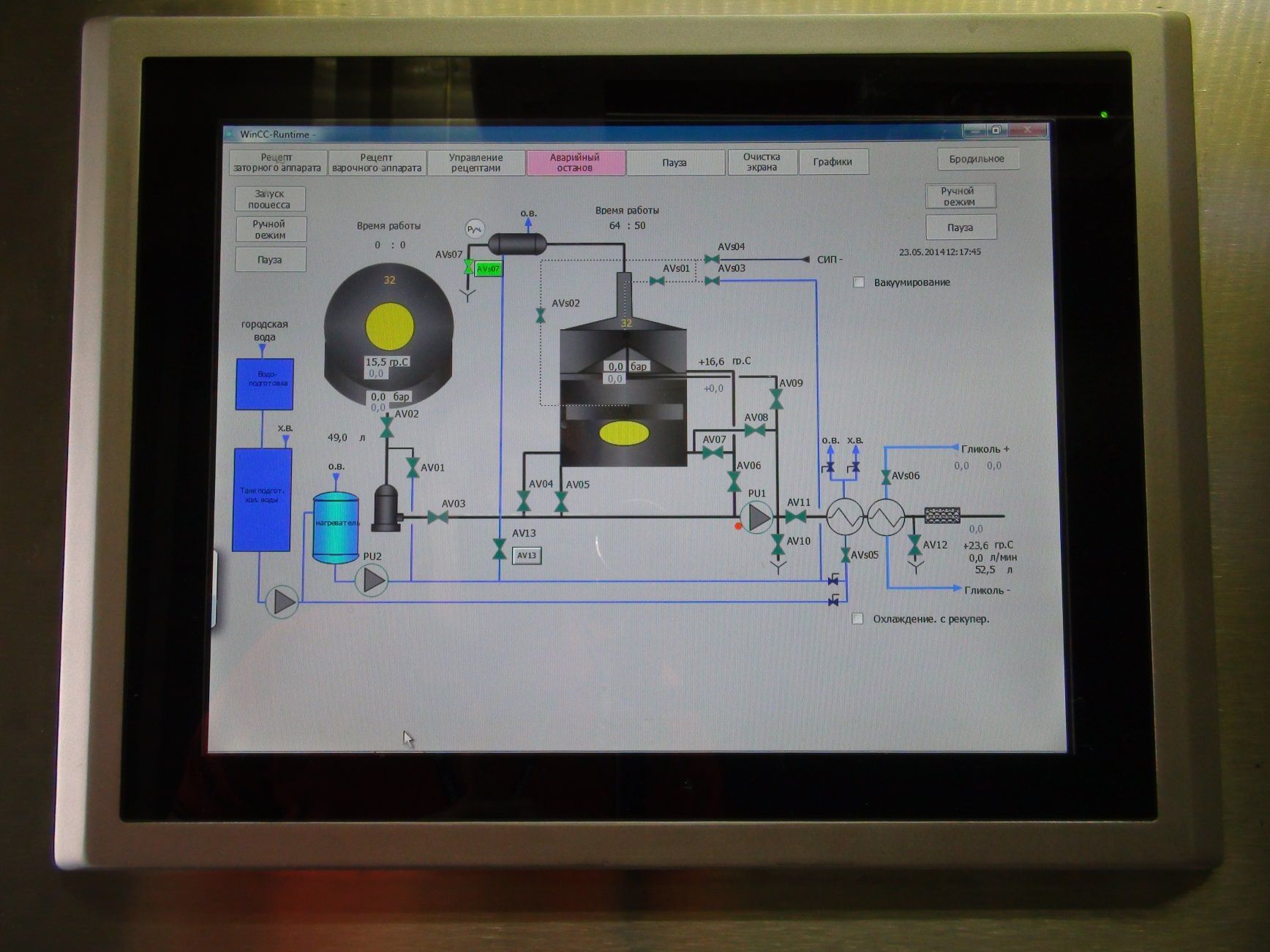

- 12. Изготовлен не базе стандартного сухогрузного контейнера

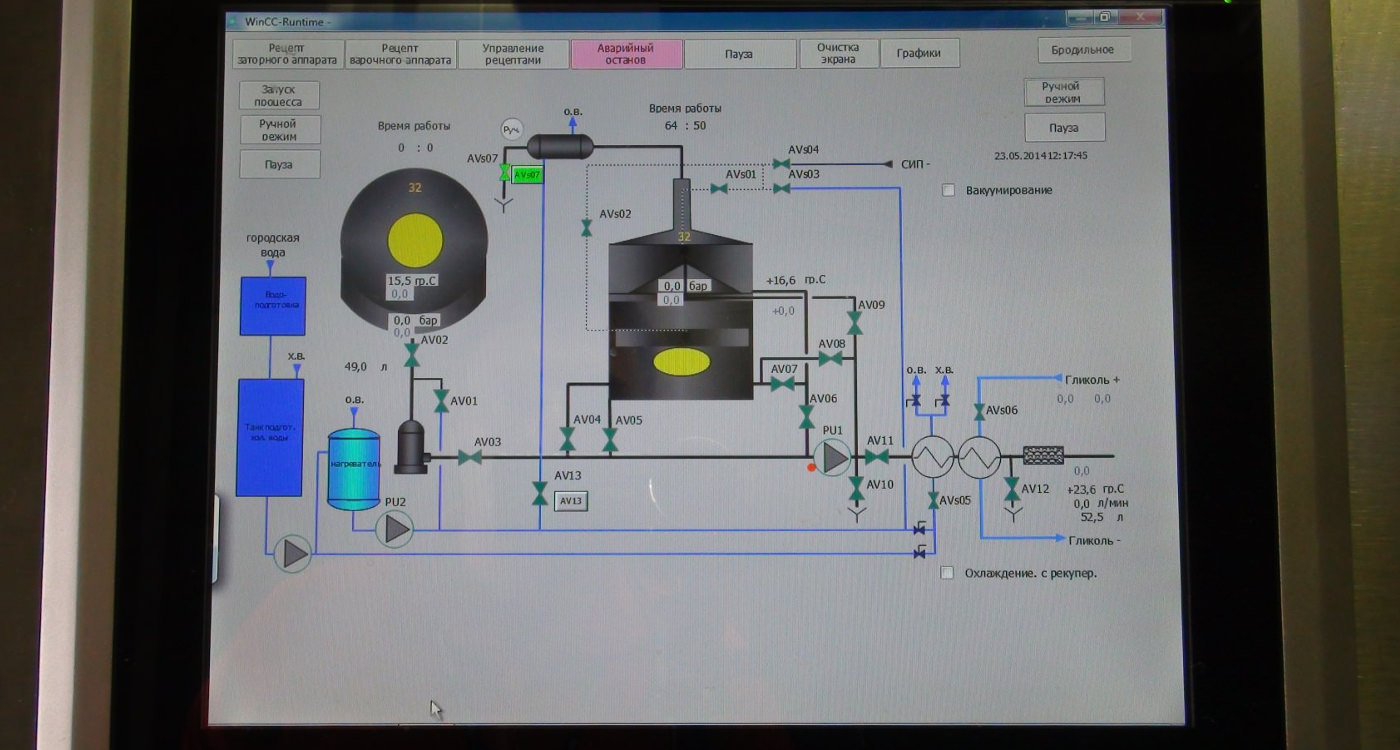

- SMART:

- 1. Все пункты комплектации CLEVER

- 2. + Автоматизированное переключение клапанов с использованием пневматики SMC - Япония

- 3. + Полная автоматизация процессов с использованием контроллеров BERGHOF – Германия

- 4. + Полный контроль технологических параметров с использованием контрольно-измерительных приборов IFM – Германия

- 5. + Полное управление в автоматическом режиме с применением сенсорной панели, с сохранением более 500 рецептов пива и возможностью удаленного контроля

- 6. + Система рекуперации тепла с бойлером и насосом

- 7. + Изготовлен на базе РЕФКОНТЕЙНЕРА с встроенной холодильной машиной

- 8. + Услуги пивовара с наладкой 4 сортов пива на выбор

IMS – Innovative Modular Systems»

Russia, 109390, Moscow, 1-st Tekstilshiki str. 12/9, office 2.

Russia, 109390, Moscow, 1-st Tekstilshiki str. 12/9, office 2.

GMP Certified Professional, к.т.н.

Chermen Kaytukov

Chermen Kaytukov

+7-926-217-57-17

© IMS Copyright 2014